Please Choose Your Language

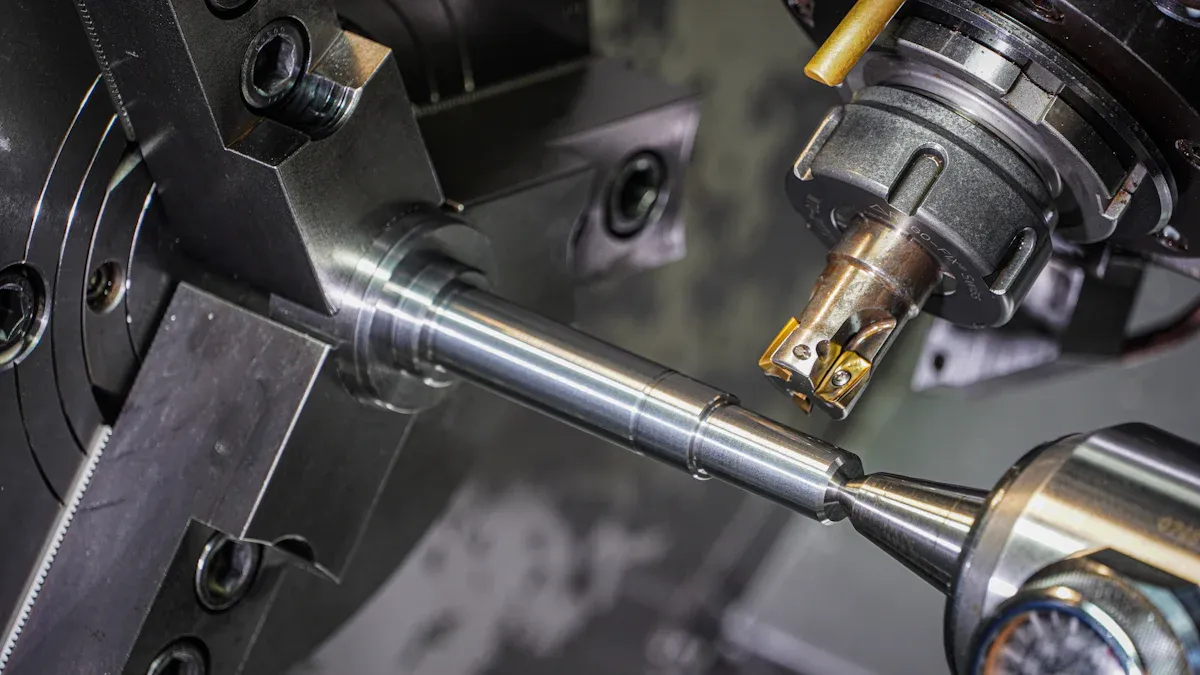

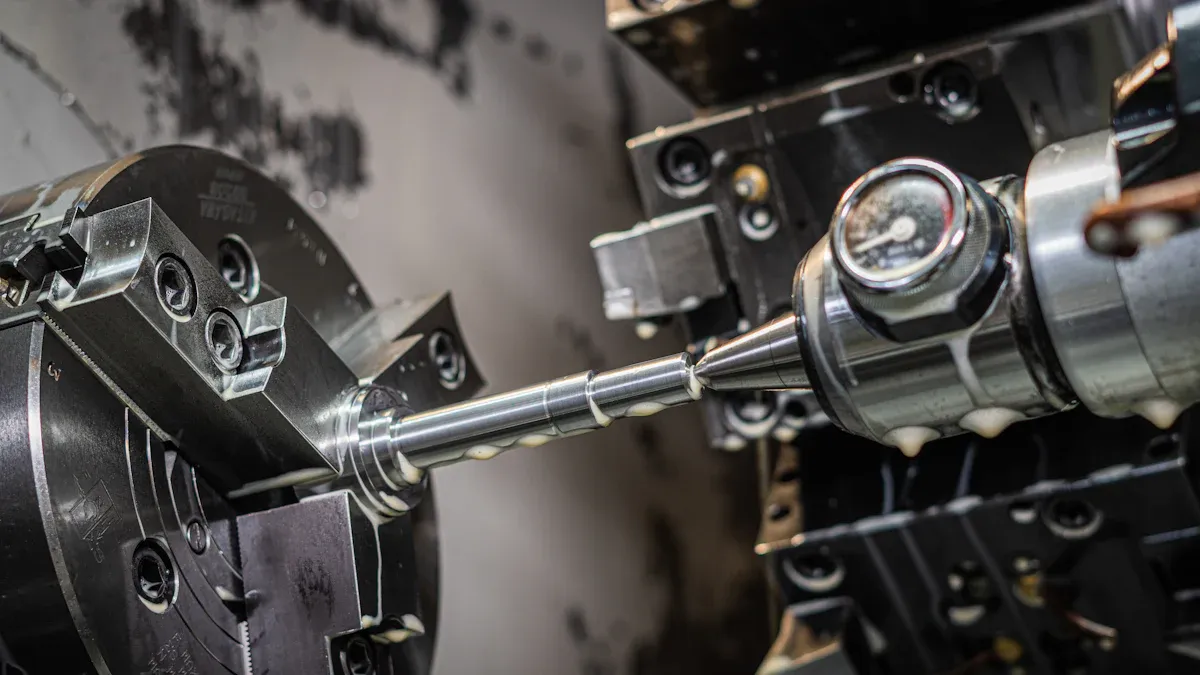

You might ask what CNC turning is. CNC means computer numerical control. Computers help control machines with this technology. The machines shape materials using computer instructions. In CNC turning, a machine spins the material. A cutting tool shapes the spinning material. Many industries use CNC turning. These include automotive, aerospace, and electronics. CNC turning helps them work faster. It also helps them make more parts. The market for these machines is growing quickly. It could reach $12.5 billion by 2033. CNC turning is common because it makes parts fast. It also makes parts very accurately.

CNC turning uses computers to control machines. It shapes materials into exact round parts. This is very important for car and airplane companies.

The CNC turning process has three main steps. First, designs are changed into computer programs. Next, the machine gets set up. Last, the parts are made.

Picking the right material is very important for CNC turning. You can use metals like stainless steel or aluminum. Each metal works best for different jobs.

CNC turning is better than doing it by hand. It is more exact, works faster, and wastes less material.

Picking a good CNC turning service helps your project. Look at their experience, what machines they have, and how they check quality.

You might wonder why CNC turning is important. CNC turning uses computer programs to run a lathe machine. The machine spins a piece of metal or plastic. A cutting tool moves straight against the spinning material. This shapes the material into round or cylinder parts. You can make detailed shapes with great accuracy. Many companies use CNC turning to make parts fast and precise. This process is special because it turns raw materials into finished parts with computer help.

Tip: If you want smooth, round parts, CNC turning is usually the best way.

You may ask how CNC turning is different from other CNC methods. The biggest difference is how the machine and material move. In CNC turning, the material spins while the tool stays still. In CNC milling, the tool moves but the material does not spin. Each method is better for certain shapes and jobs.

Here is an easy table to show the differences:

| Aspect | CNC Milling | CNC Turning |

|---|---|---|

| Direction | Cutters stay still and the material moves | The material spins while the tool does not move |

| Shapes | Makes detailed shapes that are not always round | Makes round or cone-shaped parts |

| Material Choice | Works with many materials like metal and plastic | Best for materials that need to be round |

| Production Volume | Good for small or medium batches | Great for making lots of round parts |

| Applications | Used in planes, cars, medical tools, electronics | Used in cars, medical, planes, oil and gas |

You can see CNC turning is best for making round or spinning parts. CNC milling is better for shapes that are not round. If you need many of the same round part, CNC turning is faster and costs less per part. Machines and bar feeders help make more parts quickly.

Note: CNC turning is better for making lots of parts fast. You can make thousands of parts in a short time.

You can break down the cnc turning process into three main steps. Each step helps you move from a design to a finished part with high precision.

You start by converting your CAD design file into a cnc program. This program tells the machine exactly how to move.

Next, you prepare the cnc turning machine. You mount the material, set up the tools, and check all safety measures.

Finally, you manufacture the cnc turned parts. The machine spins the material while the cutting tool shapes it. You get parts with tight tolerances and smooth finishes.

Safety Tip: Always wear personal protective equipment like safety glasses and hearing protection. Never open the machine hood until the spindle stops. Keep your hands away from moving parts and use dust extraction systems to keep the area clean. Secure the workpiece tightly to avoid accidents.

You need to know the main parts of a cnc lathe to understand how turning works. Each part has a special job that helps you achieve precision.

| Component | Function |

|---|---|

| Lathe | Spins the workpiece and positions the cutting tool for accurate shaping. |

| Chuck | Holds the workpiece tightly so it does not move during turning. |

| Cutting Tool | Removes material from the spinning workpiece to create the shape you want. |

The process starts when you mount the workpiece in the chuck. The lathe spins the workpiece at a set speed. The cutting tool moves against the spinning material and removes small amounts of metal or plastic. You can use different tools for roughing, finishing, or making complex shapes. This setup gives you control and precision for every part you make.

You must pay attention to the length-to-diameter ratio when you plan a turning job. This ratio compares how long the part is to how wide it is. If the part is much longer than it is wide, you face special challenges.

| Effect | Description |

|---|---|

| Increased Bending and Deflection | Long, thin parts bend more easily under cutting forces. This can hurt precision. |

| Vibration and Chatter | Long parts vibrate more, which can make the surface rough and shorten tool life. |

| Reduced Accuracy | It becomes harder to keep tight tolerances and the right shape because of bending and vibration. |

| Limitations on Cutting Parameters | You may need to slow down the cutting speed or take smaller cuts to avoid problems. |

| Increased Risk of Tool Breakage | Tools can break more easily when working with long, thin parts because of instability. |

You can solve these problems by supporting the part better, using the right cutting tools, and adjusting the machine settings. You should always check the length-to-diameter ratio before you start. This helps you keep your parts accurate and your tools safe.

Note: Common challenges in cnc turning include tool wear, poor surface finish, vibration, and dimensional errors. You can fix these by choosing the right tools, keeping the machine in good shape, and checking your settings often.

There are different machines for turning. Each one is good for certain jobs. The most common types are:

Turret lathes

Engine lathes

Special-purpose lathes

CNC lathes mix old lathe ideas with computer programs. These machines help you make parts as the workpiece spins. They are great for making parts that need to be very exact. Some machines, called turning and milling centers, can do both jobs. They let you make hard shapes in just one setup.

Tip: Pick the best machine for your project. If you need lots of the same part, a CNC lathe is a good choice.

CNC turning technology helps you make parts that are very exact. The computer controls every step. This means each part matches your design. You can make shapes like cylinders, cones, and threads. CNC lathes are special because they:

Are best for round or cone-shaped parts.

Can make hard shapes and threads.

Give you high accuracy for making many parts.

Help stop mistakes by using computers instead of people.

Turning and milling centers give you more choices. You can use them to add things like slots or holes.

| Component | Role in Precision and Repeatability |

|---|---|

| Spindle | Spins the workpiece smoothly and keeps it in place. |

| Turret | Holds tools and moves them to the right spot every time. |

| Control Panel | Runs the program and checks each step for mistakes. |

CNC turning technology lets you make parts as close as ±0.0001 inches. You get the same part every time. This is important for things like airplanes and medical tools.

You need to know how exact your parts should be. CNC turning machines can make parts with very small errors. Here is a quick chart:

| Tolerance Type | Achievable Tolerance |

|---|---|

| Standard Tolerance | +/- 0.005” (0.127 mm) |

| High Precision | ± 0.0025mm (about a quarter of a hair wide) |

Surface finish is how smooth or rough your part is. It matters for how your part looks and works. CNC turning gives you different finishes for different jobs.

| Surface Finish (Ra) | Description | Applications |

|---|---|---|

| 1.6 μm Ra | Good for most uses and saves money for inside parts. | Used for machine parts where looks do not matter much. |

| 3.2 μm Ra | Focuses on working well, not looking nice, and is cheap. | Used for hidden or low-contact parts. |

| 0.1 μm Ra | Very smooth, made by grinding, for top quality. | Used for tools and airplane parts that need to be perfect. |

You can choose the right tolerance and finish for your project. CNC turning lets you control both.

CNC turning is used in lots of industries. It helps make parts for cars, planes, and robots. Some main industries that use turning are:

Automotive

Aerospace

Medical

Defense

Consumer Goods

Industrial Equipment

Energy

Robotics

Furniture

Fashion

Turning makes important parts for cars and planes. These parts are found in engines, transmissions, and brakes. Here are some examples:

Engine parts like pistons and crankshafts

Transmission pieces such as gears and shafts

Suspension parts, including shock absorbers

Brake parts like brake discs

Steering system pieces

Exhaust parts, including flanges and mufflers

CNC turning has many advantages over manual turning. The table below shows how CNC turning is different:

| Benefit | CNC Turning | Manual Turning |

|---|---|---|

| Precision | Very accurate | Depends on the worker |

| Speed | Makes more parts faster | Slower to make parts |

| Complexity of Design | Can make hard shapes | Can only make simple shapes |

You can make hard shapes with great accuracy. The process is fast and every part is the same. You waste less material because the machine cuts only what you need. Smart features help save money and cut down on waste.

Tip: CNC turning lets you make better parts with less waste and lower cost.

Many materials work for turning. The best one depends on what you need. Here are some common choices:

Stainless steel: Strong and does not rust

Titanium: Light and strong for tough jobs

Carbon steel: Tough and easy to shape

Mild steel: Softer and good for detailed parts

Aluminum: Light and easy to cut

Brass and copper: Good for electrical parts

Engineering plastics: Great for light and exact parts

How hard or soft a material is changes how you machine it. Hard materials take longer but make strong parts. Softer materials are quicker for making detailed shapes. Always pick the right material for your project to get the best results.

When you plan a machining job, you should know what changes the price. Many things can make machining cost more or less. Here is a table that shows the main things that affect cost:

| Factor | Description |

|---|---|

| Material Selection | Some materials cost more and are harder to machine. |

| Part Complexity | Hard shapes need more time and skill, so they cost more. |

| Machining Time | If it takes longer to machine, it costs more. Simple parts are cheaper. |

| Quantity and Volume | Making lots of parts makes each part cheaper. Small batches cost more for each piece. |

| Machine Type and Accuracy | Fancy machines and high accuracy make the price go up. |

| Surface Preparation and Post-Processing | Extra steps like polishing or coating add more cost. |

Setup time is also important. You pay for tools, setting up fixtures, and cnc turning programming. If you only make a few parts, setup costs are split between fewer pieces, so each part costs more. If you order a big batch, setup cost for each part goes down. Batch size is very important in machining. Large batches use setup time better and make each part cheaper. Small batches mean setup is a bigger part of the total cost.

Picking the right machining service helps you get good results. You should think about these things:

Know what your project needs, like material and accuracy.

Check if the company has the right machines and skills.

Look at their experience and how people rate them.

Make sure they talk to you and answer your questions.

Ask if their prices are clear and fair.

Think about working with them for a long time.

You should also ask about how they check quality. Good companies use strong inspection steps. They follow rules like ISO 9001 or AS9100D to make sure parts are accurate. Some companies have special certificates for cnc turning programming or machine brands. These show they know the newest machining technology.

If you want custom solutions, see if the company can do special jobs. The size of the company can change how they handle your project. Always pick a service that fits your needs for machining, accuracy, and cnc turning programming.

Tip: A good machining partner helps you save money, get accurate parts, and receive parts on time.

Now you know how cnc turning works and what machines do. You also know why it is important for many industries. You can use cnc turning for small business projects. It helps you save money and gives you more design choices. It is also good for making a small number of parts.

| Benefit | Explanation |

|---|---|

| Cost-effective production | You waste less material and it is good for small batches. |

| Flexibility | You can change your design fast to help customers. |

| Precision | You get high-quality parts every time you use it. |

If you want to learn more, look for free online classes or guides about CNC machining. New ideas like smart manufacturing and AI make cnc turning even more interesting. Do you have more questions? You can ask or try cnc turning for your next project!

You use CNC turning for round parts. You use cnc mill turn machines for parts that need both turning and milling. These machines let you shape, drill, and cut in one setup. You save time and get more complex parts.

You pick a material based on strength, weight, and cost. Metals like aluminum and steel work well for most jobs. Plastics suit light parts. You match the material to your part’s needs and budget.

You can make custom parts with CNC turning. You upload your design, set the machine, and get parts that fit your project. The process gives you high accuracy and repeatability for every piece.

Turn mill programming lets you control machines that do both turning and milling. You write instructions for each step. The program helps you make complex shapes and features in one process.

You check your machine settings, use sharp tools, and measure parts often. You keep the workpiece secure and follow the right steps. Regular maintenance helps you avoid mistakes and keeps parts precise.