Please Choose Your Language

Aluminum has emerged as a go to material in the energy and infrastructure sectors due to its exceptional combination of light weight, strength, corrosion resistance, and thermal conductivity. Long celebrated for applications in aerospace and automotive industries, aluminum's unique properties are equally valuable in the large scale assemblies and harsh operating environments characteristic of wind turbines, solar arrays, bridges, and transportation systems. To fully harness these benefits, manufacturers turn to CNC machining—a computer controlled subtractive process that delivers high precision aluminum components with complex geometries, tight tolerances, and excellent surface finishes.

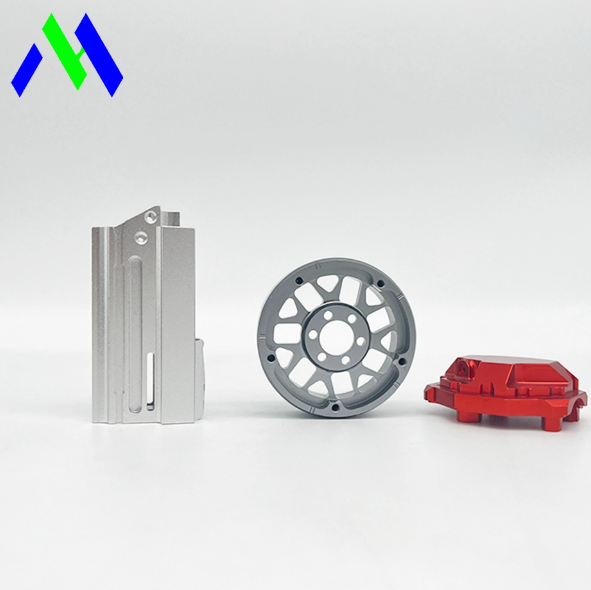

Modern utility scale wind turbines rely heavily on aluminum for non rotating structural parts and precision assemblies:

Nacelle and Rotor Hub Housings: These housings protect complex gearbox, generator, and control electronics from the elements. CNC machining creates intricate mounting interfaces, access ports, and sealing surfaces that must align with millimeter level accuracy to ensure proper lubrication and weatherproofing.

Pitch and Yaw Mechanism Brackets: The blades' pitch and the nacelle's yaw adjustments require robust aluminum brackets to bear dynamic loads. CNC machined parts provide the exact hole patterns and bearing seats necessary for smooth, responsive operation, reducing mechanical play and maintenance downtime.

Gearbox Adapter Plates: Aluminum plates connect cast iron gearbox assemblies to steel frames. CNC machining ensures flatness and hole pattern precision to distribute torque loads evenly and prevent premature fatigue.

By machining these parts from high strength aluminum alloys (e.g., 6061-T6, 7075-T73), manufacturers achieve a desirable balance of stiffness and weight savings, improving overall turbine efficiency and lowering transportation costs for large components.

Photovoltaic (PV) installations often span rooftops, parking canopies, and open fields, demanding durable yet lightweight support systems:

Rail and Clamp Assemblies: Aluminum rails and clamps secure solar modules at optimal tilt angles. CNC machining produces consistent cross sections, precise attachment features, and integrated cable management channels, facilitating rapid on site assembly.

Tracker Drive Components: Single‐ and dual axis solar trackers use CNC machined aluminum gears, sprockets, and bearing housings to achieve smooth, motor driven panel rotation. Accurate gear tooth profiles and concentric bores are critical for reliable daily tracking motions without binding or backlash.

Substructure Connectors: Brackets, gussets, and splice plates — all CNC machined — link structural members while withstanding wind uplift, seismic forces, and extreme temperature cycles. Tight dimensional control ensures uniform load distribution across the array.

Aluminum's natural corrosion resistance means these components can endure decades of outdoor exposure with minimal maintenance, contributing to lower life cycle costs for utility scale PV projects.

The energy sector relies on sophisticated electronics for power conversion, grid monitoring, and remote control:

Switchgear and Control Panel Housings: Machined aluminum panels and structural frames offer electromagnetic shielding, mechanical strength, and heat dissipation for medium and high voltage switchgear. CNC cutting, drilling, and milling produce precise cutouts for switches, displays, and cable entries.

Transformer Radiator Fins and Heat Sinks: Aluminum heat sinks machined with optimized fin geometries improve thermal performance in transformers and inverters. CNC machining can create high aspect ratio fin structures with uniform thickness and spacing, maximizing convective cooling.

Junction Boxes and Cable Glands: Custom enclosures protect fiber optic and copper connections in solar farms, wind parks, and substations. Tight sealing surfaces and screw boss details are CNC machined to guarantee IP rated weatherproofing.

With CNC machining, these enclosures achieve both aesthetic finishes and functional reliability, meeting stringent industry standards for electrical safety and environmental protection.

In modern construction, aluminum's combination of architectural appeal and structural performance is unparalleled:

Curtain Wall Frames and Mullions: CNC-machined aluminum profiles form the skeleton of glass curtain walls on skyscrapers. Precise milling of groove slots, corner brackets, and anchor points ensures seamless assembly and consistent sightlines.

Bridge Expansion Joint Covers: Aluminum cover plates protect bridges' expansion joints, accommodating thermal movement while providing skid resistant surfaces. CNC milling yields precise tongue and groove detailing for watertight interfaces.

Rail System Components: Custom tie plates, fastening clips, and rail support brackets are CNC machined from high strength aluminum alloys, offering corrosion resistance in coastal and urban environments.

These applications leverage CNC machining's ability to handle large format profiles and intricate detail work, delivering parts that meet both structural requirements and aesthetic goals for public infrastructure projects.

Beyond buildings and bridges, CNC machined aluminum parts play a key role in transportation systems:

Airport Docking Systems: Passenger boarding bridges and jetway components use aluminum for frames, guide rails, and wheel assemblies. CNC machining provides accurate mounting interfaces and sliding track geometries, ensuring smooth operation and passenger safety.

Railway Signal Enclosures: Signal heads, junction boxes, and mounting brackets require robust, weatherproof housing. CNC machined aluminum parts deliver precise cutouts for signal lenses and wiring, while maintaining corrosion resistance.

Highway Signage and Lighting Poles: Custom bases, flange plates, and reinforcement rings are CNC machined to exacting tolerances, simplifying installation and reducing field adjustments.

The lightweight nature of aluminum reduces foundation loads and simplifies handling during installation, while CNC machining guarantees the precision necessary for high speed rail and modern roadway systems.

Aluminum naturally forms a protective oxide layer that guards against corrosion. In marine, coastal, and chemically aggressive settings—common to energy and infrastructure projects—this passive film minimizes the need for additional coatings, reducing maintenance intervals and lifecycle costs.

While aluminum alloys do not match steel's absolute tensile strength, their exceptional strength to weight ratio allows designers to achieve comparable performance with significantly lower mass. Reduced component weight translates to:

Less robust support structures, lowering foundation and framing costs.

Easier transport and handling, especially for large assemblies like turbine hubs and bridge segments.

Improved dynamic performance, such as faster solar tracker response or reduced wind-induced vibration on buildings.

In electrical enclosures and heat-dissipation components, aluminum's high thermal conductivity (≈205 W/m·K) ensures efficient heat transfer, while its electrical conductivity supports well-grounded enclosures and EMI shielding.

Aluminum is highly amenable to CNC machining:

Low cutting forces reduce tool wear and energy consumption.

Good chip evacuation—especially with well-designed coolant strategies—prevents recutting and surface blemishes.

Superior surface finishes can be achieved without extensive secondary polishing, yielding Ra values below 0.4 µm in many cases.

These attributes make aluminum both cost-effective and versatile, able to accommodate complex designs without sacrificing precision.

A major solar farm developer in Southeast Asia required custom aluminum mounting brackets and junction box housings for a 200 MW photovoltaic installation. The client specified:

Brackets: 150,000 units of tilt-adjustable rail clamps, requiring hole-pattern precision within ±0.2 mm, anodized finish, and corrosion resistance for a coastal environment.

Junction Boxes: 50,000 units of die-cast-style enclosures machined from billet 6061-T6 aluminum, with integrated heat-sink fins and IP65 sealing surfaces.

Material Procurement and Validation: Ming Hao sourced certified 6061-T6 extrusion billets and performed incoming chemical and mechanical tests to confirm alloy composition and strength.

CNC Machining Strategy:

Brackets: Machined on dual-spindle CNC mills with pallet changers, enabling simultaneous roughing and finishing to maintain high throughput. Automated tool measurement and adaptive feed control ensured hole positions held within ±0.15 mm.

Junction Boxes: Machined on 5 axis CNC centers to form complex fin geometries and sealing surfaces without secondary fixtures. High pressure coolant and specialized carbide end mills achieved Ra ≤ 0.3 µm on critical sealing faces.

Surface Treatment: Post machining, aluminum parts underwent precision anodizing to enhance corrosion resistance and provide a uniform grey finish.

Quality Assurance:

In process probing checked hole patterns and sealing flanges.

Final inspection on CMMs validated overall dimensions against CAD models.

Statistical Process Control (SPC) tracked key dimensions, ensuring consistent quality across batches.

On Time Delivery: All 200,000 components delivered within the six week project timeline.

First Pass Yield: Exceeded 98%, minimizing rework and scrap.

Lifecycle Performance: Deployed parts showed no signs of corrosion or dimensional drift after 18 months of coastal exposure, validating material choice and machining quality.

CNC machining of aluminum parts has become indispensable for the energy and infrastructure industries, offering a powerful combination of precision, durability, and efficiency. From wind turbine components and solar panel structures to architectural frames and transportation systems, CNC-machined aluminum delivers the exacting tolerances and complex geometries that modern projects demand. With natural corrosion resistance, excellent strength-to-weight ratio, and superior thermal properties, aluminum ensures long service life even in the harshest environments.

At Dong Guan Ming Hao Precision Molding Technology Co., Ltd., our advanced CNC capabilities and rigorous quality systems enable us to support large-scale deployments while maintaining tight tolerances and rapid turnaround times. By partnering with Ming Hao, project developers and engineering teams gain access to the expertise and precision needed to drive sustainability, reduce maintenance costs, and accelerate deployment schedules.

Whether you're designing the next generation of renewable energy installations or building resilient infrastructure for growing urban populations, CNC-machined aluminum parts provide the reliability and performance foundation your projects require. Trust Ming Hao to deliver precision-engineered solutions that transform your visions into enduring realities.