Please Choose Your Language

CNC Machining lets you make strong and exact parts. These parts work well in hard oil and gas places. You need these parts for safe and steady drilling. They also help with extraction and refining. When you use Machining Services, you get parts like:

Turbine blades and rotors for power plants

Pump and valve parts that handle high pressure

Seals and gaskets that stop leaks and keep systems safe

Ming Hao helps with your special needs. They give fast and high-quality solutions. You can even order just one piece. Their skilled team helps you make better products for the future.

CNC Machining makes strong parts. These parts are very precise. They help keep oil and gas work safe.

Customization lets people make special parts. These parts fit each project’s needs. This helps work go faster.

Machining with high precision lowers the chance of leaks. It also stops breakdowns. This keeps equipment working well.

Using tough materials like stainless steel helps parts last longer. Specialty alloys also help in rough places.

CNC Machining cuts down on waste. It saves money by making only needed parts. Fewer mistakes mean lower costs.

Quick sample delivery from companies like Ming Hao helps projects stay on track. It also helps keep costs low.

New machining methods, like multi-axis machining, make things more accurate. They also help finish work faster.

CNC Machining uses eco-friendly ways. This helps protect the environment. It uses fewer resources and makes less waste.

You work in a field where every part must be perfect. Oil and gas jobs need parts that can handle heat, pressure, and tough chemicals. CNC Machining helps by making strong and exact parts. The table below lists what most oil and gas parts need:

Requirement | Description |

|---|---|

Precision | Parts must fit perfectly and work right. They need to be measured very closely, sometimes less than a millimeter. |

Durability | Equipment must last in hot and rough places. CNC Machining lets you pick the best materials for each job. |

Material Selection | You can use metals, plastics, or composites to match what you need. |

Scalable Production | You can make lots of parts fast and save money. The quality stays high. |

CNC Machining makes sure every part fits well and lasts long.

You need safe and steady equipment every day. CNC Machining gives you parts that help stop accidents and keep things working. With CNC Machining, you get:

Tight tolerances help safety valves and other key parts work in tough spots.

Strong parts last longer and break less, so you have fewer problems.

Careful checks make sure every part is good before it leaves the shop.

Tip: Good parts mean fewer problems and safer places for your team.

Choosing CNC Machining helps keep your workers and your tools safe.

Every oil and gas job is special. Sometimes you need big, tough parts or parts made just for your project. CNC Machining lets you design and order what you want, like:

Valves, seals, and pressure regulators made with care for pipelines and refineries

Threaded fittings, elbows, and couplings for tight connections

Pump housings, impellers, and pistons for strong fluid systems

Special fasteners like bolts, nuts, washers, and screws for rigs and pipes

Pressure relief valves, regulators, and manifolds for controlling flow

You can pick strong alloys and materials that fight rust for your job.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps with custom orders. You can order just one piece, and their team can finish samples in 24 hours. They offer many surface finishes and colors, like sanding, anodizing, and electroplating. Their experts work with you to make your project better and give you full service. With Ming Hao, you get quick, high-quality, and custom solutions for oil and gas work.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. is a trusted company for good machined parts. You can count on their advanced CNC machines. They use milling, turning, multi-axis machining, sheet metal work, laser cutting, and bending. Ming Hao lets you customize your order, even if you only need a few parts. They send samples quickly. Their team has worked in many industries and offers many surface finishes. You get all the help you need in one place. They make your oil and gas work easier and faster.

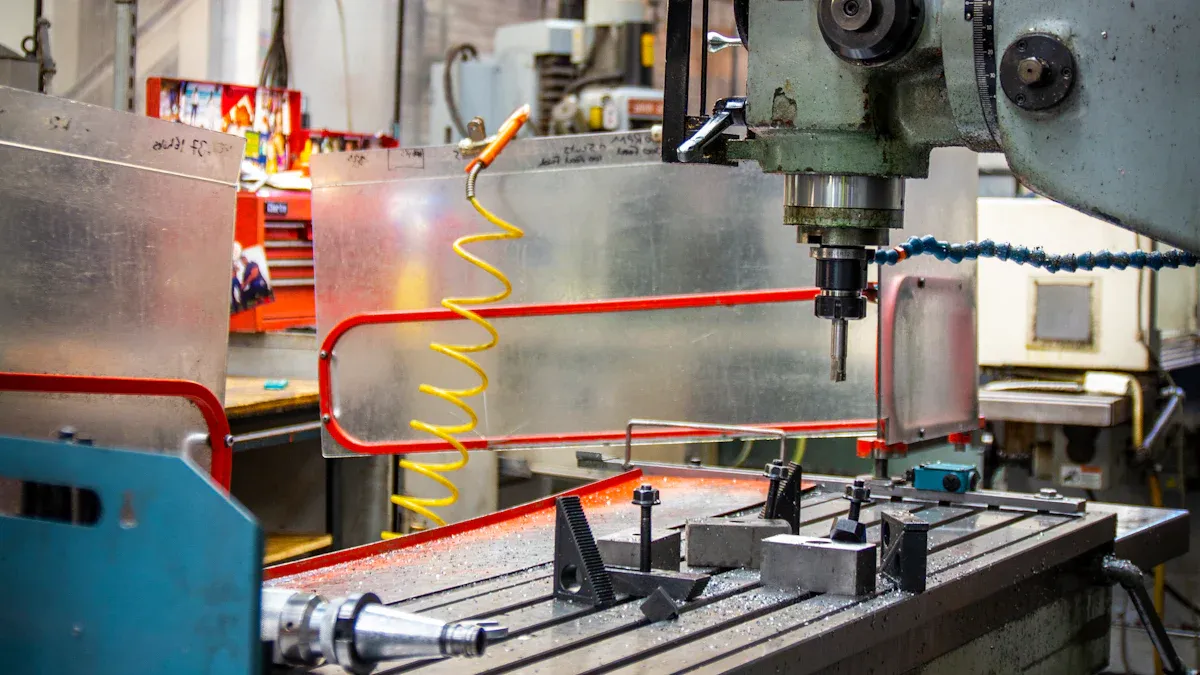

CNC milling shapes parts from solid blocks. Milling machines cut away material with spinning tools. They make flat surfaces, slots, holes, and tricky shapes. Oil and gas jobs need parts that fit well and last in tough places. Milling helps you make:

Drill bits and collars for high pressure underground

Pump housings and valve bodies to control flow

Flanges and brackets for pipelines

CNC milling makes sure parts fit tightly. You can pick strong metals or special alloys that fight rust, heat, and pressure. This method lets you make hard parts fast when you need quick fixes. Ming Hao uses advanced machines, like 3-axis and 5-axis centers, for speed and accuracy.

Note: Even a small size mistake can cause big trouble in oil and gas gear. CNC milling helps you avoid costly stops.

CNC turning shapes round parts by spinning them and cutting with a tool. You use turning for:

Valves

Fittings

Couplings

Hydraulic parts

Turning centers and lathes make parts with very close sizes, sometimes as close as ±0.0001 inches. You get smooth, strong parts ready to use. Turning also makes shapes that are hard to do by hand. Ming Hao’s turning services give you the same good quality every time, whether you need one part or many.

Advantage | Description |

|---|---|

Precision | Gets very close sizes, better than manual lathes. |

Repeatability | Makes the same part every time, no matter how many you need. |

Complex Geometry Capabilities | Can make tricky shapes that are hard with manual turning. |

Reduced Human Error | Less human work means fewer mistakes and bad parts. |

Improved Surface Finish | Makes smooth surfaces, so you often don’t need extra work. |

Integration with CAD/CAM | Makes it easy to go from design to finished part. |

Enhanced Safety | Safer because people do less work during machining. |

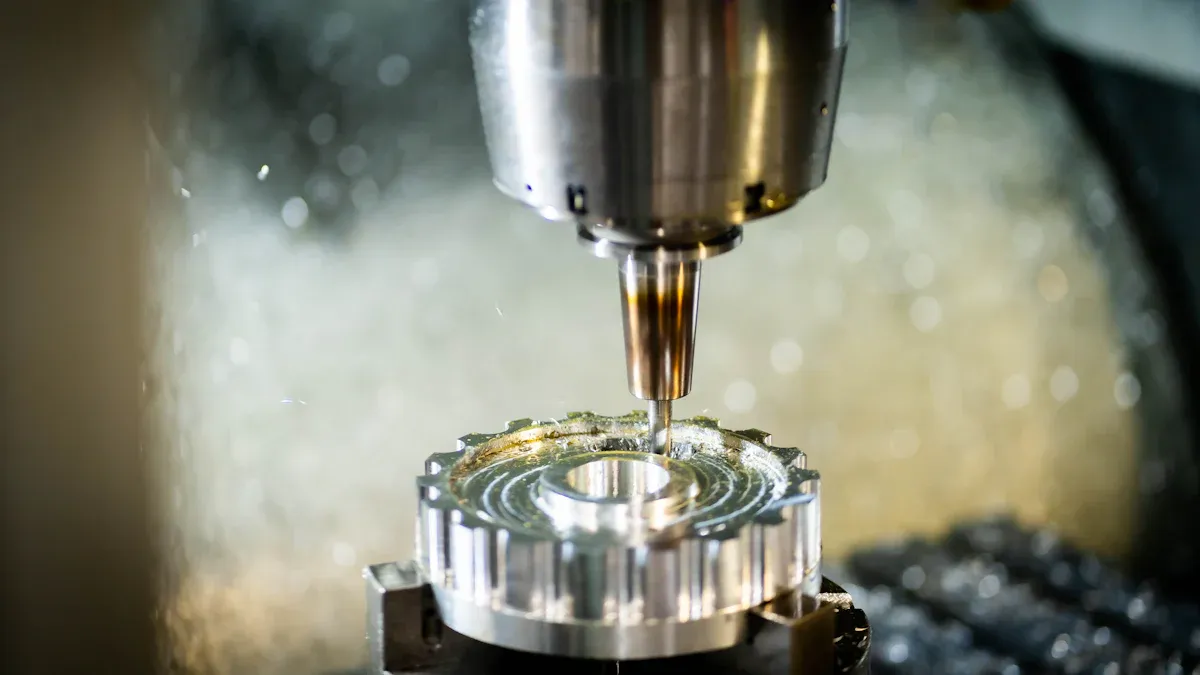

Multi-axis CNC machining moves the cutting tool in many ways at once. You use this for parts with tricky shapes and close sizes. In oil and gas, you need multi-axis machining for:

Wind turbine and compressor blades

Downhole tools with special grooves or holes

Custom manifolds and pump parts

Multi-axis machines, like 5-axis centers, help you make parts you can’t make with simple machines. You get better accuracy and smoother surfaces. Ming Hao’s multi-axis machining lets you make advanced parts for tough oil and gas jobs. This method helps you meet strict rules and gives you reliable parts for the field.

Tip: Multi-axis machining saves time and cuts mistakes by working on all sides of a part in one setup.

Sheet metal processing plays a big part in oil and gas projects. You use sheet metal to make both large and small parts that must stand up to tough jobs. With CNC Machining, you can shape, cut, and bend metal sheets into many forms. This method gives you strong, light, and exact parts for your equipment.

You often see sheet metal parts in drilling and extraction. For example, you need:

Drill bits, casings, and wellheads for drilling equipment

Pipes and pipelines that move oil and gas

Storage tanks for crude oil and finished products

Frames and panels for offshore platforms

Sheet metal also helps you build many smaller parts. These include:

Pins, spacers, and springs

Shafts and fasteners

Connectors and bushings

Vacuum barriers and sealing systems

Valving and actuating systems

Pump parts, drill bit parts, and stuffing boxes

Blowout preventers and hydraulic components

You choose sheet metal because it lets you make parts quickly and in many shapes. You can pick from different metals, such as stainless steel or special alloys, to match your needs. Sheet metal parts often need to fit with other equipment, so you must get the size and shape just right.

Tip: Good sheet metal work helps you avoid leaks, breaks, and costly repairs in the field.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. supports you with advanced sheet metal processing. Their team uses the latest CNC Machining, laser cutting, and bending tools. You can order custom parts, even if you only need one. Ming Hao finishes samples in 24 hours and offers many surface treatments, like sanding, anodizing, and electroplating. Their experts help you pick the best design and material for your job. You get one-stop service, from design to finished part.

If you want to improve your oil and gas equipment, you can trust Ming Hao for high-quality, custom sheet metal parts. They work with you to make your project better and safer.

Parts must fit together just right. In oil and gas, mistakes can cause leaks or breakdowns. CNC Machining uses computers to cut and shape with great accuracy. This makes parts that match your plans. Your equipment works better and lasts longer.

A skilled manufacturer gives you even more accuracy. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. uses advanced machines and checks every part. Their team makes sure each part meets your needs. You can trust them for custom jobs, even the hard ones.

Tip: Accurate parts help you avoid repairs and keep things running well.

You want to save time and money on your projects. CNC Machining helps by making things faster and more reliable. Here is how it helps you work better:

You need fewer machines and workers, so you save money.

The process cuts down on mistakes, so you get better parts.

You do not have to move parts between many machines.

You spend less time checking work, so there are fewer errors.

Automation helps you control and track your work.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. gives fast samples and helps with small orders. Their team uses new technology to help you finish on time and stay on budget.

Oil and gas equipment faces tough conditions every day. You need parts that handle high pressure, heat, and strong chemicals. CNC Machining gives you strong and reliable parts. The table below shows how this helps parts last longer:

Description | Key Points |

|---|---|

High precision and reliability of critical components | Enhances durability in harsh environments |

Precisely matched components from turning and milling machines | Essential for flawless functioning of machinery |

Products withstand high pressures | Increases operational effectiveness and safety |

Precision and consistency reduce leaks and malfunctions | Decreases environmental issues and boosts durability |

You can trust CNC Machining to make parts that last and work well. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. uses top materials and checks quality. Their team helps you pick the best options, so your equipment stays strong and safe.

You need equipment that fits your exact needs. Oil and gas projects often change. Sometimes you need a new part fast. CNC Machining gives you the power to create custom parts for any job. You can make simple or complex shapes, from small fittings to large housings. This process lets you adjust designs quickly, so you can solve problems as they come up.

CNC Machining helps you in many ways:

You can make parts with complex shapes and fine details.

You can order one part or many, depending on your project.

You can choose from many strong materials, like stainless steel or special alloys.

You can change designs fast if your needs change.

Note: Custom parts help you keep your equipment running, even in tough places.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. supports your need for flexibility. Their team uses the latest CNC milling, turning, and multi-axis machines. You can order just one piece or a large batch. They finish samples in 24 hours and offer many surface finishes, such as sanding, anodizing, and electroplating. You get help with design, material choice, and production. Ming Hao works with you to make sure your parts fit your needs.

Oil and gas work must meet strict rules. You need parts that match industry standards for safety and quality. CNC Machining helps you meet these rules every time. The process uses computers to cut and shape parts with high accuracy. This means your parts fit together well and work as they should.

Here is how CNC Machining helps you stay compliant:

Precision cutting makes sure each part fits perfectly, so you avoid leaks and misalignment.

Customization lets you match exact sizes and shapes for your project.

Careful checks and tests make sure every part meets the right standards.

Compliance Benefit | How It Helps You |

|---|---|

High Precision | Reduces risk of failure and keeps systems safe |

Custom Dimensions | Ensures parts work with your other equipment |

Quality Control | Every part gets checked before it leaves the shop |

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. takes compliance seriously. Their team checks every part for quality. They use advanced machines and skilled workers to meet your needs. You can trust Ming Hao to help you follow industry rules and keep your equipment safe.

Drilling equipment must work in hard places. It keeps your work going. CNC Machining makes strong and exact parts for drilling. Many drilling parts are made with precision machining. These parts face high pressure, heavy weight, and harsh chemicals.

Some common CNC machined parts in drilling equipment are:

Hydraulic fracturing fluid ends

Directional drilling collars, subs, and mandrels

Artificial lift components like pockets and bodies

Sub-sea stack components

Blow out preventer (BOP) parts

Drill rig parts such as top drives, links, quills, mandrels, yokes, and pins

Frac valve bodies and flowline components

Gearbox parts and actuators

These parts help you drill deeper and safer. Good machined parts lower the chance of breakdowns. They help keep your team safe. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. gives you custom solutions for these needs. Their team sends samples fast, even if you need just one. This helps you keep your project moving.

Valves and pumps move oil, gas, and fluids in your system. You need them to work without leaks or problems. CNC Machining lets you make tricky shapes and tight seals for valves and pumps. This helps you move thick fluids and handle hot or cold temperatures.

You will find CNC machined parts in:

Ball valves for cryogenic and high-pressure uses

Pump housings with special shapes for better flow

Valve bodies and seats that stop leaks

Actuators and stems for precise control

CNC Machining gives you parts that fit well and last longer. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. uses new machines to make these parts. Their team helps you design custom valves and pumps. You can pick from many materials and finishes. This makes your equipment work better and last longer.

Tip: Custom valves and pumps help stop leaks and keep your system safe.

Pipelines carry oil and gas far. You need pipeline parts that stay strong and work well, even in tough places. CNC Machining gives you the accuracy needed for important pipeline parts.

Key pipeline parts made with CNC Machining are:

Flanges and connectors for tight, leak-free joints

Casing hangers and manifolds for safe flow control

High-pressure umbilical components

Riser system parts and dual completion block valves

These parts help you build new pipelines and fix old ones. If a part breaks, you need a fast and good replacement. CNC Machining lets you get strong parts quickly, so you have less downtime. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps you with fast service and steady quality. Their team works with you to design and deliver the right parts every time.

Pipeline Part | Function | Benefit |

|---|---|---|

Flanges | Connects pipes securely | Prevents leaks |

Manifolds | Distributes flow | Improves system control |

Casing Hangers | Supports pipe weight | Increases safety |

Umbilical Components | Transfers fluids and signals | Handles high pressure |

Ming Hao gives you one-stop service, from design to finished part. You can order custom pipeline parts, even in small amounts, and get samples in 24 hours. Their experts help you pick the best materials and finishes for your job.

You need downhole tools that work deep underground. These tools face lots of pressure, heat, and strong chemicals. CNC Machining helps make parts that last in these hard places. You use downhole tools for drilling, measuring, and controlling oil and gas wells. Each tool must be strong and made just right.

Many downhole tools use special materials. These materials help the tools survive tough conditions. The table below shows how different materials and methods help your tools stay safe and work well:

Material Type | Purpose in Extreme Conditions |

|---|---|

Inconel | Used in corrosive environments due to its strength. |

Hastelloy | Provides resistance to high temperatures and corrosion. |

Super duplex stainless steels | Offers durability in abrasive formations. |

CNC Milling and Turning | Maintains thread tolerances for reliable tool joints. |

Integrated Inspection Systems | Enables real-time measurement to ensure quality. |

CNC Machining makes parts like drill collars, stabilizers, and logging tools. These parts need tight threads and smooth surfaces. If a thread is not right, the tool might break. CNC Milling and Turning help you get the right fit every time.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps you with custom downhole tools. Their team uses advanced machines and strong materials. You can order one tool or many. Ming Hao finishes samples in 24 hours and checks every part for quality. You get tools that work well and last longer.

Tip: Strong downhole tools help you drill deeper and keep your wells safe.

You want to test new ideas before making many parts. Rapid prototyping lets you see how a part works and fits. CNC Machining helps you make prototypes fast and with good quality. You can change designs quickly and try different shapes or materials.

The table below shows the benefits of rapid prototyping and small batch production for oil and gas:

Benefit | Description |

|---|---|

Reduced Risk | Early identification of design flaws reduces the risk of costly errors in full-scale production. |

Flexibility in Design | CNC machinery allows for complex designs that may be too costly with other methods, fostering innovation. |

Rapid Development and Iteration | Enables quick creation and testing of multiple design versions, essential for innovation in the energy sector. |

High Precision and Quality | Ensures prototypes meet exact specifications, crucial for performance and safety in energy applications. |

Material Versatility | Can work with various materials, allowing prototypes to mimic final product properties for effective testing. |

Cost-Effective Solutions | More economical than traditional methods, reducing tooling costs and facilitating small production runs. |

Efficiency in Production | Streamlines the process from concept to final product, crucial for timely deployment in the energy sector. |

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps you with rapid prototyping and small batch orders. You can order just one piece. Their team finishes samples in 24 hours. You get high-quality prototypes that match your needs. Ming Hao offers many surface finishes and color choices. Their experts help you test and improve your designs.

If you want to make new products or test ideas, Ming Hao gives you fast and reliable service. You get one-stop support, from design to finished part.

Note: Rapid prototyping helps you find problems early and make your products better before full production.

Stainless steel is used a lot in oil and gas work. This metal does not rust easily. It can handle heat and strong chemicals. Stainless steel parts last longer in tough places. They also stay strong when it gets very hot. That is why people use it for valves, pumps, and downhole tools.

Here are some grades you might pick:

Grade | Properties | Applications |

|---|---|---|

2205 Duplex | Very strong, fights rust, and handles lots of stress. | Oil & Gas parts, Heat exchangers, Marine jobs |

17-4PH | Good against rust, strong in less harsh places. | Aerospace, Oil & Gas work |

You can choose the grade that works best for your job. 2205 Duplex is good for places with lots of pressure and saltwater. 17-4PH is strong and does not rust much in easier spots. Using stainless steel helps stop leaks and keeps things working.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. can make these grades for you. Their team uses CNC machines to shape stainless steel into custom parts. You can order one part or many. They finish samples fast and check each part for quality.

Tip: Stainless steel makes your equipment last longer and keeps your site safe.

Carbon steel is strong and tough. You use it for big jobs in oil and gas. This metal can take high pressure and hard hits. Carbon steel costs less than many other metals. It helps you save money on big projects.

Here are some good things about carbon steel:

Advantage | Description |

|---|---|

High strength and toughness | Good for heavy jobs, great for oil and gas parts. |

Excellent machinability | Lets you make tricky and exact shapes, needed for hard parts. |

Good weldability | Easy to put together and fix, helpful for repairs. |

Cost-effectiveness | Cheaper than other strong metals, good for saving money. |

You can use carbon steel for flanges, fittings, and pipeline parts. It is also good for frames and supports. If you need to fix or weld a part, carbon steel makes it easier.

Ming Hao helps you with high-quality carbon steel parts. Their team helps you pick the right grade and finish. You get strong, custom parts for your project.

Note: Carbon steel is a smart pick when you want strength and a good price.

Non-ferrous metals do not have iron in them. You use them when you want special things, like less weight or better rust protection. Some common ones are aluminum, copper, and brass. These metals help you make parts that last longer and work better in tough oil and gas jobs.

Here is how non-ferrous metals help your equipment:

Property | Benefit in Oil and Gas Equipment |

|---|---|

Corrosion Resistance | Makes parts last longer in harsh places. |

Lightweight | Makes equipment lighter and easier to use. |

Excellent Machinability | Helps you make tricky parts with good detail. |

You might use aluminum for covers and housings. Copper and brass are good for fittings and connectors. These metals make your equipment lighter and easier to move. They also help stop rust and damage from chemicals.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. can make non-ferrous metal parts for you. Their team uses CNC machines to make custom parts. You can order a few or many, and they finish samples fast.

Tip: Non-ferrous metals give you more ways to build strong, light, and rust-proof parts.

Sometimes, you need parts that work in very hard jobs. Regular metals might not be strong enough for oil and gas work. Specialty alloys give extra strength and protect your equipment. These alloys help your tools last longer in tough places.

Specialty alloys are used in many oil and gas tools. They help keep valves, pumps, and downhole tools safe from harm. Some alloys stop rust and corrosion. Others stay strong when it gets very hot. You choose the right alloy for your job.

Here is a table with popular specialty alloys for CNC machining in oil and gas:

Alloy Type | Examples | Key Properties |

|---|---|---|

Nickel-based superalloys | Inconel, Hastelloy, Waspaloy | High strength, corrosion resistance, high temperature stability |

Cobalt-based superalloys | N/A | Wear resistance, often used in medical applications |

Iron-nickel-based | Incoloy | Cost-effective, good mechanical properties under stress |

Nickel-based superalloys like Inconel and Hastelloy are very strong. They can handle high heat and strong chemicals. You use them for parts deep underground or near hot fluids. Iron-nickel alloys like Incoloy are strong and cost less. Cobalt-based alloys do not wear out fast, but they are mostly for medical tools.

Tip: Specialty alloys help stop breakdowns and keep your site safe, even in hard jobs.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. works with these strong alloys. Their team uses new CNC machines to shape tough materials. You can order custom parts, even just one. Ming Hao finishes samples in 24 hours and checks each part for quality. You get strong, reliable parts that fit your needs.

If you want better oil and gas equipment, Ming Hao can help with high-quality specialty alloys. Their experts help you pick the best material for your project. You get help from design to finished part. Ming Hao is ready to help you make better products.

You often need to machine very hard materials for oil and gas equipment. These materials, like stainless steel and titanium, help your parts last longer in harsh places. Working with them brings special challenges:

You must reach high precision when cutting hard metals. Even a small mistake can cause leaks or breakdowns.

Large and complex shapes are tough to make. You need advanced machines and skilled workers.

Tools get very hot and wear out quickly. High temperatures and pressure during machining can damage both the tool and the part.

The energy market changes fast. Sometimes, you may not have the newest machines because of budget limits.

When you choose a partner like Dong Guan Ming Hao Precision Molding Technology Co., Ltd., you get help with these problems. Their team uses the latest CNC Machining technology and has deep experience with hard materials. They support you with custom solutions, fast sample delivery, and strong quality checks.

Tip: Using the right machines and skilled workers helps you get better results with hard materials.

Oil and gas work must follow strict rules. You need every part to meet high standards for safety and quality. CNC Machining helps you make parts that fit these rules. You use it to make:

Pistons

Valves

Rods

Cylinders

Pins

Each part must stop leaks and work well under pressure. If a part fails, it can cause big problems, like spills or lost resources. You need high-precision parts to keep your site safe and efficient. CNC Machining lets you use strong metals, such as stainless steel and titanium, which handle tough jobs in drilling and extraction.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. checks every part before it leaves the shop. Their team makes sure your parts meet all industry standards. You can trust them to help you follow the rules and keep your equipment safe.

Making large parts for oil and gas equipment is not easy. You face many challenges:

You must create complex shapes with tight tolerances.

Tough materials, like stainless steel and titanium, need powerful machines and skilled workers.

Heat builds up in big parts, making it hard to keep the right size and shape.

You also deal with:

Heat generation, which can change the quality of your finished part.

Stress and distortion, which make it hard to keep large parts accurate.

Extra setups, like special fixtures and tools, to hold and machine big pieces.

Inspection difficulties, since large parts have complex surfaces and are hard to measure.

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps you solve these problems. Their team uses advanced machines and smart setups to handle large parts. They offer one-stop service, from design to finished product, and support you with fast samples and custom orders.

Note: Careful planning and the right machines help you make large parts that last longer and work better.

Oil and gas sites are some of the hardest places to work. There is high pressure, very hot temperatures, and strong chemicals. Your equipment must keep working, even when things get tough. CNC Machining helps by making parts that last a long time and work well.

You need parts that fit just right in these harsh places. CNC Machining gives you parts that do not break under stress. This means you have fewer leaks and less time when things stop working. Your valves, fittings, and connectors keep working, even if it gets hotter or colder.

Here is a table that shows how CNC Machining helps your equipment in tough places:

Application | Description |

|---|---|

Valves | CNC Swiss machining makes valves that handle high pressure and heat in oil and gas jobs. |

Fittings | This technology makes strong fittings that do not break in tough spots. |

Connectors | CNC machining makes connectors that fit tightly, so there are fewer leaks. |

You get these benefits:

Parts made with care for hard oil and gas jobs.

High-precision parts that seal better and stop leaks.

Reliable parts that last longer and need fewer repairs.

When you pick Dong Guan Ming Hao Precision Molding Technology Co., Ltd., you get more than just tough parts. Their team uses the newest CNC Machining tools and smart ways to make parts. They work with many materials, like stainless steel and special alloys. You can order custom parts, even if you need only one. Ming Hao can finish samples in 24 hours and offers many finishes, like sanding, anodizing, and electroplating. Their experts help you choose the best design and material for your job. You get help from start to finish.

Tip: Strong and exact parts help you save money and keep your site safe, even when things get really hard.

Ming Hao wants to work with you for a better future. Their team helps you get safer and more reliable oil and gas equipment.

You want to keep your project costs low. CNC machining helps you do that in many ways. When you use CNC machines, you need fewer workers. The machines do most of the work. This means you spend less on labor. CNC machining also makes fewer mistakes. You do not waste money fixing errors or making new parts.

You can order only the number of parts you need. You do not have to buy large batches. This helps you save money on storage and unused parts. Fast production means you finish your projects on time. You avoid delays that can cost you more.

Tip: Choosing a company with fast sample delivery, like Dong Guan Ming Hao Precision Molding Technology Co., Ltd., helps you save even more. You get your parts quickly and keep your project moving.

CNC machining helps you use materials wisely. The machines cut parts with high accuracy. You do not waste metal or plastic. Less waste means you spend less on raw materials. You also help the environment by making less scrap.

Here are some ways CNC machining reduces waste:

Machines cut only what you need for each part.

You can reuse leftover material for other jobs.

You make fewer mistakes, so you throw away fewer parts.

You can recycle metal chips and scraps.

Method | How It Reduces Waste |

|---|---|

Precise Cutting | Uses only needed material |

Reusable Offcuts | Saves leftovers for future |

Fewer Mistakes | Less scrap and rework |

Recycling | Turns waste into new parts |

Dong Guan Ming Hao Precision Molding Technology Co., Ltd. uses advanced CNC machines. Their team helps you design parts that use less material. You get strong, high-quality parts and help protect the environment.

You care about the future of the planet. CNC machining supports your goals for a cleaner world. The process uses less energy than many old methods. You make less waste and use fewer resources. This helps lower your carbon footprint.

CNC machining lets you choose materials that last longer. Stronger parts mean you replace them less often. You use less energy and fewer resources over time. Many CNC shops, like Dong Guan Ming Hao Precision Molding Technology Co., Ltd., recycle metal scraps and use eco-friendly practices.

Note: When you work with Ming Hao, you support green manufacturing. Their team uses smart designs and efficient machines. You get custom parts, fast delivery, and help build a better future.

Ming Hao welcomes you to join them in making oil and gas work safer, cleaner, and more cost-effective. You get one-stop service, from design to finished part, with a focus on quality and sustainability.

When you pick CNC machined parts for oil and gas, you help your equipment last longer. The lifecycle means every step, from design to when you replace the part. Knowing these steps helps you save money and keep your site safe.

Stages of the CNC Machined Part Lifecycle:

Design and Customization

You begin by making parts that fit your job. Customization lets you fix special problems. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. gives advice and sends samples fast. You can order one part and get it in just 24 hours.

Production

CNC machining shapes strong materials with special tools. You get parts that are smooth and fit well. Ming Hao uses new machines for milling, turning, and multi-axis work. Their team checks each part to make sure it is good.

Installation and Use

You put the parts into your equipment. Good machining means the parts fit and work right away. You will see fewer leaks, less breaking, and fewer safety problems.

Maintenance

Strong CNC machined parts do not break often. You do not spend much time fixing things. If you need a new part, Ming Hao can make it fast.

Replacement and Recycling

After a long time, some parts wear out. You can recycle metal parts and get new CNC machined ones. This helps make less waste and is better for the planet.

Tip: Picking strong materials and careful machining makes parts last longer. You save money and help the environment.

Lifecycle Benefits Table

Stage | How CNC Machining Helps You | Ming Hao’s Support |

|---|---|---|

Design | Custom solutions for your project | Fast samples, expert advice |

Production | High precision, strong materials | Advanced machines, quality checks |

Installation | Easy fit, reliable performance | One-stop service |

Maintenance | Fewer repairs, quick replacements | Small batch orders, fast delivery |

Replacement | Easy recycling, sustainable choices | Material and finish options |

You can control each step of the lifecycle with the right partner. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. helps you at every stage. Their team gives one-stop service, from design to finished part. You get help with custom orders, small batches, and many finishes like sanding, anodizing, and electroplating.

If you want your oil and gas equipment to last and work better, think about the whole lifecycle. Good CNC machining gives you strong, safe, and earth-friendly parts. Ming Hao wants to help you build a better future in oil and gas.

CNC Machining makes building oil and gas equipment easier. You get strong and exact parts that keep your work safe. These parts also help your job run smoothly. If you pick a skilled company like Dong Guan Ming Hao Precision Molding Technology Co., Ltd., you get custom help and quick service. Their team uses new machines and gives you everything in one place. Soon, CNC Machining will use more robots and eco-friendly ways. This helps you work better and care for the earth.

CNC machining uses computers to control machines that cut and shape metal or plastic. You get parts that are very accurate and strong. This process helps you make custom parts for many uses.

You need parts that can handle high pressure, heat, and chemicals. CNC machining gives you strong, exact parts that last longer. This helps you keep your equipment safe and working well.

You can use stainless steel, carbon steel, aluminum, copper, brass, and special alloys. Each material has different strengths. You pick the best one for your job.

You can get samples from Dong Guan Ming Hao Precision Molding Technology Co., Ltd. in as little as 24 hours. They support small orders, even just one piece, and help you finish your project quickly.

Yes, you can order only one part. Dong Guan Ming Hao Precision Molding Technology Co., Ltd. supports small orders. You get help with design, material choice, and surface finish.

You get one-stop service, fast samples, and many surface finishes. Their team uses the latest CNC machines and works with many materials. They help you with custom designs and support you from start to finish.

CNC machining uses less material and makes less waste. You can recycle metal scraps. This process helps you save resources and protect the planet.