Please Choose Your Language

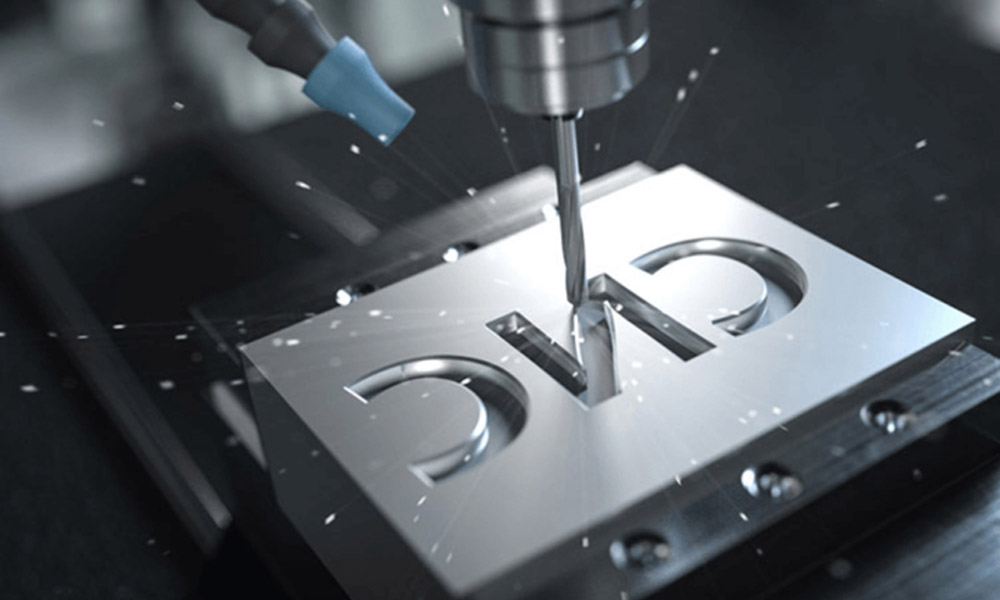

Our High Precise Custom OEM CNC Machining Aluminum Stainless Steel Brass Parts CNC Milling Service delivers ultra-precision components for industries demanding tolerance control and material versatility. Leveraging advanced 5-axis CNC milling centers (DMG Mori NHX series) and multi-spindle turning technologies, we specialize in producing complex parts from aluminum 6061/7075, stainless steel 304/316, and brass C36000 with ±0.01 mm dimensional accuracy . Our integrated workflow—from CAD design validation to post-processing inspection—ensures consistent quality across production runs, with surface finishes as smooth as Ra 0.8 μm for critical applications in aerospace and medical sectors.

| Availability: | |

|---|---|

| Quantity: | |

![]()

| Name | High Precise Custom Oem Cnc Machining Aluminum Stainless Steel Brass Parts Cnc Milling Service |

| Material | Aluminum Brass Steel |

| Surface treatment | Painting\Powder Coating\Plating\Polishing |

| Certification | ISO9001-2015 |

| Our Service | ODM CNC Machining Service.Machining-assembly |

| Service | CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping |

| Model Number | oem |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Mould material | Aluminum,Brass/Copper, Steel,Carbide tungsten,etc |

| Design software | UG, CAD, PRO/E, ect |

| Tooling Machine | CNC Milling/Turning/EDM/Wire cutting/Grinding/QC |

![]()

![]()

Anodising

Sandblasting

Silkscreen

DLC Coating

Electroplating

Nickel plating

Polishing

Laser Marking

![]()

Aluminum

Copper

Stainless steel

Plastic

| Main Materials | |

| Aluminum | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

| Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper | C11000, C12000, C12200, C10100, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Powder Coated, Nickel Plated Etc. |

| Plastic | Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving |

Achieve ±0.005 mm tolerance on micro-components (e.g., 0.5mm diameter medical implants) and ±0.01 mm on larger structures (e.g., 500mm industrial brackets) using high-speed spindles (24,000 RPM) and Heidenhain closed-loop feedback systems for real-time error correction .

Support for multi-axis simultaneous machining (3/4/5-axis) enables creation of intricate geometries like turbine blades with 3D contouring and optical mounts with angular precision of ±0.001°.

Process aluminum alloys (6061-T6 for structural parts, 7075-T6 for high-strength applications), stainless steel (304 for corrosion resistance, 316 for marine environments), brass C36000 (for electrical conductivity), copper, titanium Ti-6Al-4V, and engineering plastics (PEEK, POM) .

Specialized handling for high-hardness materials (HRC 40–60) using carbide tooling and coolant-through spindles, plus heat-resistant alloys (Inconel 718, Hastelloy X) for aerospace engine components.

Offer type II/III anodizing (12–25 μm thickness), electrolytic passivation (per ASTM A967), textured powder coating (60–80 μm), electroplating (nickel, chrome, gold), and laser engraving (0.05mm depth precision) .

Medical-grade parts undergo 134°C autoclave testing (20 cycles) and biocompatibility certification (USP Class VI) to ensure safety in surgical applications.

Prototype orders completed in 3–5 days with SLA 3D printing integration for pre-production validation, reducing design iteration time by 40% .

Scale to low-to-medium volume production (100–10,000 parts/month) using automated tool changers (40+ tool stations) and AI-driven scheduling to minimize setup times by 25%.

Aerospace: Turbine components (with 0.02mm profile accuracy), landing gear brackets (load-tested to 10,000 lbs), and satellite housings (weight-optimized by 15%).

Medical: Surgical forceps (Ra 0.4 μm finish), orthopedic implants (ISO 13485 compliant), and MRI-compatible devices (non-magnetic materials only).

Automotive: High-performance engine valves (tolerance ±0.008mm), transmission components, and EV battery connectors (conductivity tested to 500A).

Industrial: Robotics joints (repeatability ±0.01mm), pneumatic valve bodies, and precision fixtures (with CMM-verified alignment).

Design for Manufacturability (DFM) Support: Free CAD file analysis (SolidWorks/STEP formats) within 24 hours to optimize part geometry, reduce tooling costs, and improve production efficiency.

Full Traceability: QR-code labeling linking to digital inspection reports, material certification reports (mill test certificates per EN 10204 3.1), and batch-specific process logs for aerospace compliance.