Please Choose Your Language

Sheet metal fabrication is a crucial process in modern manufacturing, used to transform metal sheets into specific shapes and components through various techniques like cutting, bending, punching, and welding. The versatility of sheet metal fabrication makes it essential across many industries, including automotive, aerospace, electronics, and construction. This process is key to producing high-precision parts that are integral to the functionality and performance of various products.

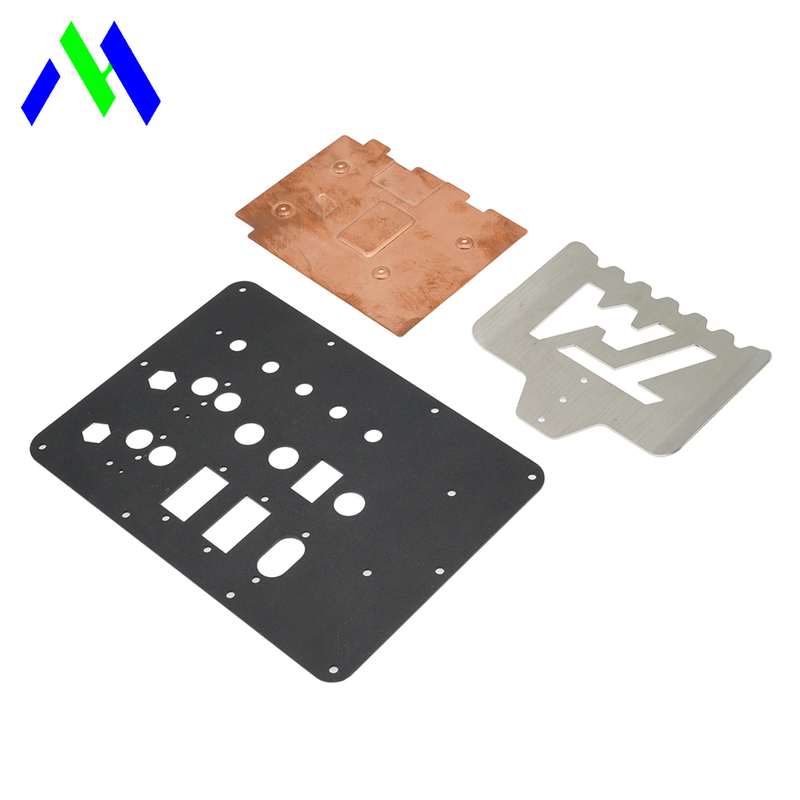

Sheet metal fabrication refers to the process of transforming metal sheets (typically ranging in thickness from 0.5mm to 6mm) into various parts or products through a combination of cutting, bending, welding, and other techniques. This process is widely used in industries that require durable, lightweight, and customizable components. The materials typically used in sheet metal fabrication include metals such as aluminum, stainless steel, copper, and steel.

Sheet metal fabrication involves several critical steps:

Cutting: Shaping the metal sheet using tools like lasers, shears, or water jets.

Bending: Forming the sheet into the desired shape using press brakes or other bending machines.

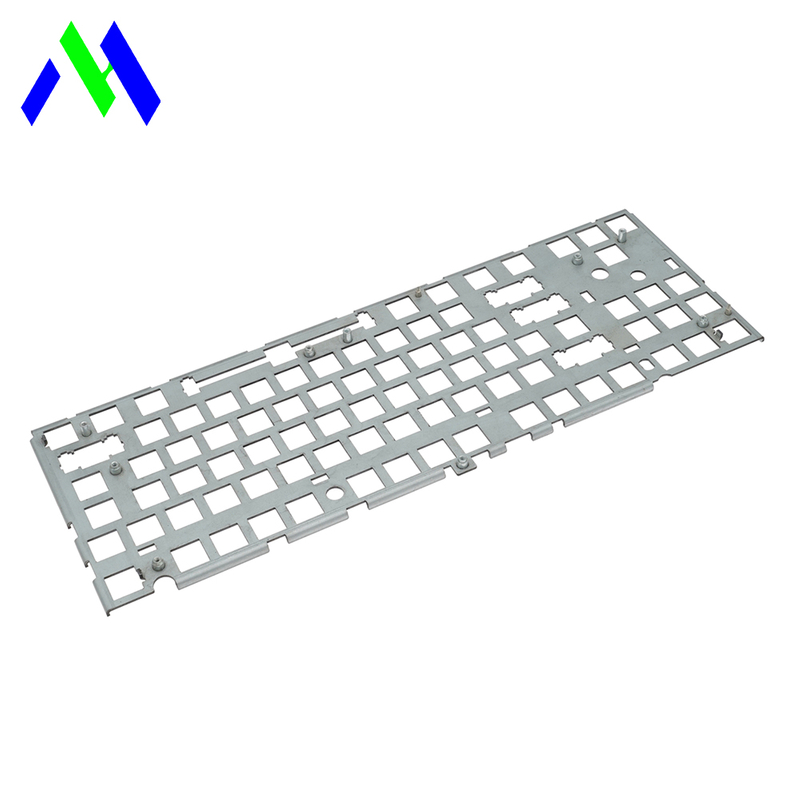

Punching: Creating holes or shapes in the metal sheet using a punch press.

Welding: Joining metal parts together by applying heat and pressure.

These steps are typically customized based on the design and application requirements of the project.

Several techniques are commonly used in sheet metal fabrication to create the desired shapes and components. These include Laser Cutting and Sheet Metal Bending, which are two of the most widely used methods.

Laser cutting is a precise and efficient method that uses a high-energy laser beam to cut metal sheets. The laser melts and vaporizes the material in the path of the beam, resulting in a clean and accurate cut. This method is ideal for complex shapes and intricate designs.

High Precision: Achieves tight tolerances, making it suitable for complex parts.

Efficiency: Offers fast cutting speeds, making it ideal for large-scale production.

Flexibility: Capable of cutting a wide range of materials and complex shapes.

Laser cutting is widely used in automotive, aerospace, electronics, and construction industries, providing high-quality, repeatable cuts for precision components.

Sheet metal bending is a process where metal sheets are bent at specific angles to form parts with precise shapes. This process is commonly used to create brackets, enclosures, frames, and many other parts used in a variety of industries.

High Precision: CNC-controlled bending machines ensure that each bend meets the design specifications.

Strength: Bending can improve the strength and rigidity of the material, making it suitable for load-bearing components.

Material Utilization: Bending minimizes material waste, improving the efficiency of the process.

Sheet metal bending is used across industries like automotive, electronics, construction, and appliances to create functional and structural components.

This table could summarize the key fabrication steps and the tools or techniques involved. It could also list typical materials used in each process step.

| Process | Tools/Techniques | Materials Used | Typical Applications |

|---|---|---|---|

| Cutting | Laser cutting, Water jet cutting, Shearing | Steel, Aluminum, Brass, Copper, Stainless Steel | Automotive parts, Electronics enclosures |

| Bending | Press brake, CNC bending machine | Aluminum, Stainless Steel, Copper, Brass | Structural components, frames, brackets |

| Punching | Punch press, CNC punching machine | Steel, Aluminum | Creating holes, slots, and shapes in metal sheets |

| Welding | MIG welding, TIG welding, spot welding | Steel, Aluminum, Stainless Steel | Assemblies, structural frames, enclosures |

| Assembly | Manual or robotic assembly | Steel, Aluminum, Stainless Steel, Plastic | Final product assembly, enclosures |

Sheet metal fabrication is an essential process across various industries, providing parts and components used in everything from vehicles to buildings. The applications of sheet metal fabrication are vast, and it plays a vital role in manufacturing products that require durability, strength, and precision.

In the automotive industry, sheet metal fabrication is used to create body panels, frames, support structures, and interior components. Precision-cut and bent parts are integral to car assembly, ensuring both functionality and safety.

The aerospace industry requires sheet metal fabrication for parts like aircraft fuselages, wing structures, engine housings, and more. Due to the critical nature of these components, precision and material strength are key considerations in their fabrication.

Sheet metal fabrication is used extensively in electronics for creating enclosures, connectors, and other structural components. These parts are necessary to house and protect sensitive electronic components, ensuring both functionality and safety.

In construction, sheet metal fabrication is used for producing items like ventilation ducts, roofing panels, and architectural components. The strength and versatility of sheet metal make it ideal for both structural and decorative applications in buildings.

Many household appliances, such as refrigerators, washing machines, air conditioners, and microwave ovens, rely on sheet metal fabrication for their external casings and internal support structures. These components need to be durable, well-formed, and precise to function effectively.

| Material | Properties | Advantages | Common Applications |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good conductivity | Easy to machine, excellent for outdoor environments | Aerospace, automotive, construction, transportation |

| Stainless Steel | High strength, corrosion-resistant, durable | Great for high-stress applications, long-lasting | Food processing, medical devices, automotive |

| Copper | High conductivity, corrosion-resistant | Excellent for electrical components, thermal applications | Electronics, power generation, plumbing |

| Steel (Mild) | Strong, versatile, easy to fabricate | Cost-effective, widely available, durable | Construction, automotive, heavy equipment |

| Titanium | Lightweight, high strength-to-weight ratio | Excellent corrosion resistance, biocompatible | Aerospace, medical implants, high-end manufacturing |

| Brass | High corrosion resistance, easy to machine | Aesthetic, great for applications requiring good electrical conductivity | Electronics, jewelry, decorative items |

While sheet metal fabrication is highly efficient and versatile, there are common challenges that manufacturers face during the process. These include issues related to dimensional accuracy, material properties, and the complexities of certain fabrication techniques.

Hole deformation can occur during the bending process when the material around the hole stretches or compresses unevenly. This can be minimized by:

Using the proper bending shape: Opt for a bending design that reduces the stress around holes.

Increasing pressure on the top sheet: This ensures more consistent deformation.

Adding grid patterns: Adding friction patterns to the sheet can help prevent slippage during bending.

To maintain the shape and dimensional accuracy of bent parts, manufacturers often use precision machines with CNC controls. This ensures that each bend is made according to strict specifications, reducing variability and ensuring consistency.

Cracks or fractures can happen during the bending process if the material is too brittle or the bending radius is too tight. This can be addressed by:

Using ductile materials: These materials are more flexible and less likely to crack.

Adjusting bending radius: Ensuring that the radius is sufficient to avoid stress concentration that could cause fractures.

To ensure a smooth surface after cutting, manufacturers employ high-precision cutting methods like laser cutting, which minimizes burr formation and ensures a clean edge. Additional surface treatments, such as deburring or sanding, are used when needed.

Sheet metal fabrication is typically performed using metals like aluminum, stainless steel, copper, and mild steel. Each material is selected based on the required strength, weight, corrosion resistance, and other functional properties.

Surface treatments are used to enhance the performance of fabricated sheet metal parts, especially in terms of corrosion resistance, wear resistance, and aesthetic appearance. Common surface treatment processes include:

Anodizing: Primarily used for aluminum parts to increase corrosion resistance and provide a decorative finish.

Electroplating: Applying a thin layer of metal (such as nickel or chrome) to improve durability and resistance to corrosion.

Powder Coating: Used for adding a smooth, durable finish to a variety of materials.

These processes not only extend the life of the product but also enhance its appearance and functionality, making it more suitable for a wide range of industries.

Maintaining consistent quality is critical in sheet metal fabrication to ensure that each component meets the required standards. To guarantee the quality of the final products, manufacturers follow strict quality control procedures:

ISO 9001 Certification: Ensures adherence to global quality standards.

Dimensional checks: Performed using advanced equipment to ensure precise measurements.

Process inspections: Random inspections during production to monitor consistency and identify potential issues early on.

Final product inspection: A comprehensive check to ensure that the fabricated part meets design specifications and functionality.

Quality control is an essential part of the fabrication process, helping to deliver parts that are both accurate and reliable.

MHAO Precision Molding Technology Co., Ltd. is your trusted partner for high-quality sheet metal fabrication. We specialize in providing precision-cut, bent, welded, and assembled components for various industries. Here's why you should choose MHAO:

Custom Solutions: We offer personalized services, tailoring every aspect of the fabrication process to meet your unique requirements.

High-Quality Assurance: Our ISO 9001 certification ensures that all our products undergo strict quality control at every stage of production.

Expert Team: With over 20 years of experience, our team of engineers and technicians has the expertise to deliver top-quality results.

On-Time Delivery: We understand the importance of deadlines, and we ensure that your products are delivered on time, every time.

Comprehensive Support: From product design to assembly and shipping, we provide end-to-end solutions, ensuring a seamless experience for our customers.

We invite you to partner with us for all your sheet metal fabrication needs, and together we can create high-performance, precision-engineered components.

Sheet metal fabrication is an essential manufacturing process used across a wide range of industries to create components that are durable, precise, and tailored to specific needs. Whether it's laser cutting, bending, or welding, this process ensures that every part performs its function effectively. By partnering with a skilled manufacturer like MHAO, you can be confident that your sheet metal components will meet the highest quality standards, delivered on time, and customized to your specifications.

What is sheet metal fabrication?

Sheet metal fabrication is a process that involves transforming flat metal sheets into functional parts using techniques such as cutting, bending, welding, and punching. It is commonly used in industries like automotive, aerospace, and construction.

What is the difference between laser cutting and sheet metal bending?

Laser cutting is used to cut metal sheets with high precision, while sheet metal bending involves forming the sheet into specific shapes by applying force at designated angles.

What materials can be used in sheet metal fabrication?

Common materials include aluminum, stainless steel, mild steel, copper, and titanium. The choice of material depends on the application, required strength, and environmental conditions.

How do you ensure the precision of sheet metal parts?

Precision is ensured through the use of CNC-controlled machines, laser cutting, and strict quality control measures. This allows manufacturers to meet tight tolerances and produce consistent, high-quality parts.

What industries benefit from sheet metal fabrication?

Sheet metal fabrication is widely used in industries such as automotive, aerospace, electronics, construction, and appliance manufacturing. It is ideal for creating structural components, housings, frames, and enclosures.