Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

![]()

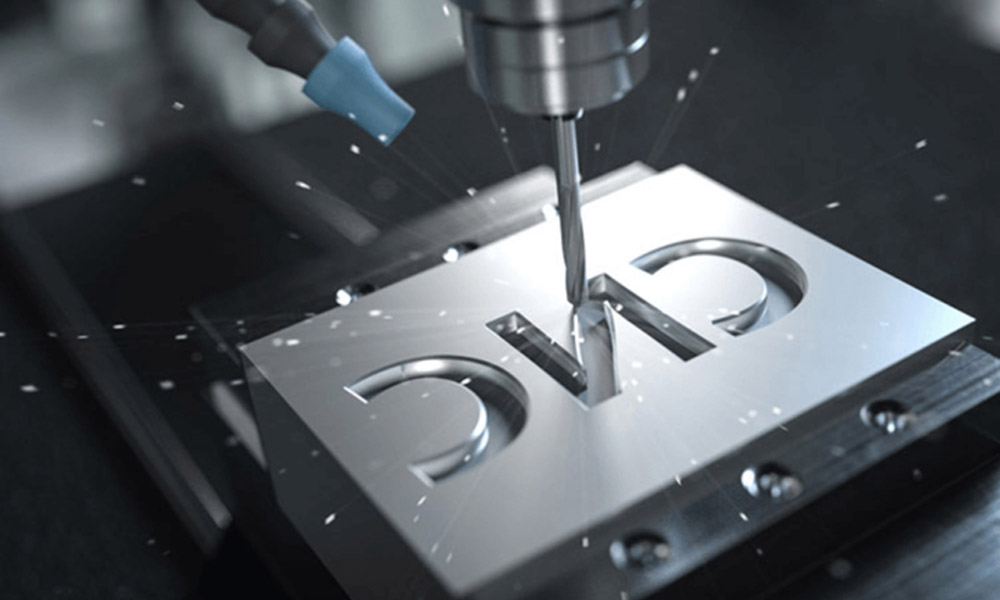

| Processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Name | Custom High Precision Stainless Steel Aluminium CNC Machined Auto Spare Parts |

| OEM/ODM | OEM ODM Non-standard Processing |

| Surface treatment | Anodizing |

| QC Control | 100% Inspectin |

| Size | According to client requirements (drawing) |

| Material | Aluminum, Brass, Bronze, Copper, Stainless steel, Steel Alloys etc |

| Surface Treatment | Chrome plating, Zinc Plating, Painting, spray-paint, Sandblasting, Powder Coating, Anodized etc |

| Process | Stamping, Turning, Bending, Grinding, Punching, Laser Cutting, Lathe, Welding, Milling |

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

| Package | Industrial package or according to clients' requirement |

Leveraging 5-axis CNC machining centers (specifically DMG MORI duoBLOCK 6000 and Haas UMC-750) and Swiss-type lathes (Star SR-32J), we specialize in producing stainless steel 316L (for corrosion resistance) and aluminum 7075 (for high strength-to-weight ratio) parts with ±0.005 mm tolerance . From transmission shafts with complex splines to valve bodies with precision bores, our solutions combine burr-free surfaces (Ra ≤0.8 μm) with intricate geometries, ensuring OE-level performance for automotive, medical, and industrial applications.

Achieve ±0.002 mm roundness on small-diameter shafts (e.g., 2mm diameter medical guide rods) and ±0.01 mm straightness on long components (e.g., 500mm hydraulic cylinder rods) using Heidenhain closed-loop feedback systems and oil-mist lubricated high-speed spindles (45,000 RPM) .

Support for multi-axis milling-turning (live tooling with 12-station turrets) to create helical gears (DIN 5 quality) and cross-drilled holes (±0.02 mm positional accuracy) in a single setup, reducing lead time by 30%.

Process high-strength alloys (Inconel 718 for high-temperature applications, titanium Ti-6Al-4V for aerospace) and non-ferrous metals with minimum feature size of 0.1 mm (e.g., micro-grooves for fluid dynamics) .

Specialized handling for biocompatible materials (stainless steel 316L) using cleanroom-grade coolant systems (ISO Class 7) and dedicated tooling to prevent contamination, critical for medical device components like surgical instrument shafts.

Bar feeder systems (FMB Turbo 510) enable continuous production of long-shaft parts (length-to-diameter ratio 30:1) with zero setup time between batches, supporting volumes up to 50,000 parts/month .

AI-driven predictive maintenance (powered by Fanuc FIELD system) reduces machine downtime by 25%, ensuring consistent lead times (3–15 days) even for complex geometries.

Offer nitriding (case depth 0.1–0.3 mm, hardness 500HV) for wear resistance, electropolishing (Ra ≤0.2 μm) for hygienic medical surfaces, and PTFE coating (thickness 10–20 μm) for low-friction automotive components.

Aerospace parts undergo eddy current testing (ASTM E2437) and X-ray inspection to detect subsurface cracks, ensuring compliance with AS9100D .

Automotive: Turbocharger turbine housings (balance tolerance ≤0.01g·mm), EV battery terminal connectors (conductivity ≥40 S/m), and CV joint yokes (fatigue tested to 10⁷ cycles).

Medical: Implantable orthopedic screws (USP Class VI compliant), laparoscopic instrument shafts (Ra 0.4 μm finish), and MRI-compatible brackets (non-magnetic 316L).

Aerospace: Turbine blade root slots (±0.005 mm profile accuracy), landing gear actuator rods (static load 20,000 N), and avionics mounting plates.

Industrial: Hydraulic valve spools (leak rate ≤0.1 cc/min at 3000 psi), bearing races (roundness ≤0.003 mm), and precision lead screws (thread pitch error ≤0.01 mm/300 mm).

Reverse Engineering: Convert physical samples into CAD models using Artec Eva 3D scanning (accuracy ±0.02 mm) and Geomagic Design X software, with tolerance analysis reports included.

Complex Geometry Solutions: Expertise in micro-machining (features ≤0.5mm) for sensor components and deep hole drilling (aspect ratio 20:1) for oil & gas flow meters.

Full Compliance: ISO 9001:2025 and AS9100D certifications, with First Article Inspection Reports (FAIR) and PPAP documentation (levels 1–5) for automotive and aerospace clients .