Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

![]()

| Product name | Oem Custom Cnc Turning Aluminium processing Machining Parts |

| Material | Aluminum, stainless steel, copper,bronze,iron |

| Size or shape | According to customer drawings or requests |

| Surface treatment | Anodizing,Polishing,Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating,blacken Ect. |

| MOQ | 1 Piece |

| Service | Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts,etc. |

| Tolerance | +/- 0.005 mm |

| Drawing accepted | CAD, PDF, SOLIDWORKS, STP, STEP, IGS, etc. |

| Certification | ISO9001:2015 |

| Package | Inner pearl button,wooden case,or customized. |

| Color | Customized Color |

| Our se | OEM & ODM service |

| Processing procedure | Laser cutting, cnc punching, cnc bending, riveting, welding, polishing, assembly |

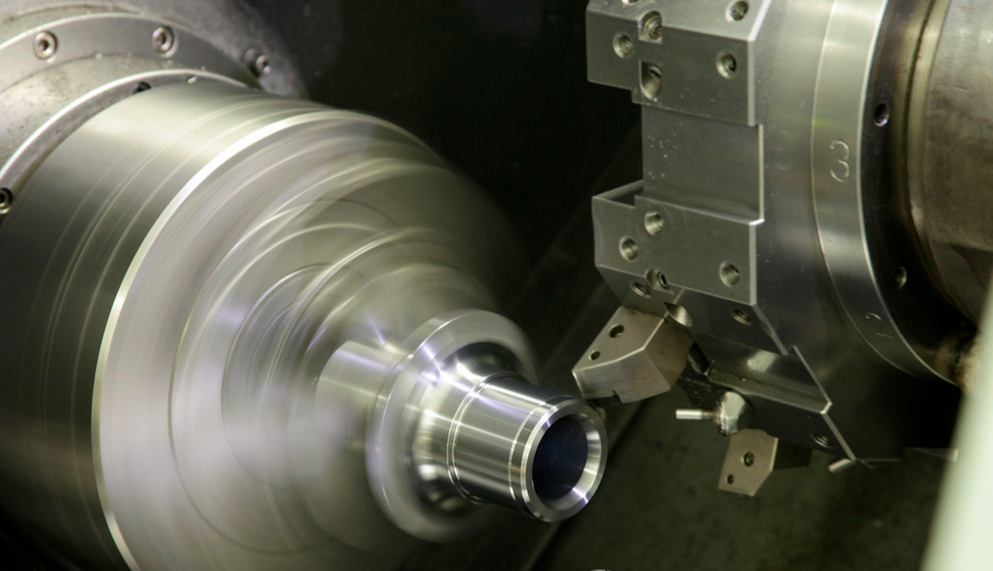

Our CNC Turning Parts Machining Services deliver high-precision cylindrical components for industries demanding rotational symmetry and tight tolerances. Using Swiss-type CNC lathes (Tsugami and Citizen models) with live tooling and sub-spindles, we produce parts from aluminum 6061, stainless steel 304, and PEEK with ±0.005 mm dimensional accuracy . From transmission shafts to precision bushings, our solutions combine complex geometries (e.g., multi-diameter shafts with keyways) with cost-effective mass production (10,000–1,000,000 parts/year) supported by automated quality control.

Achieve ±0.002 mm roundness on small-diameter shafts (e.g., 2mm diameter medical guide wires) and ±0.01 mm on larger components (e.g., 100mm diameter flanges for hydraulic systems) using high-speed spindles (45,000 RPM) and closed-loop coolant systems that maintain consistent temperature .

Support for multi-axis turning (5-axis) with live tooling to create helical grooves, cross-drilled holes, and millimeter-scale features in a single setup, eliminating secondary operations.

Process metals (aluminum, stainless steel, brass, titanium) and engineering plastics (PEEK, POM, Nylon) with minimum feature size of 0.1 mm (e.g., micro-threads for electronics) .

Specialized handling for high-temperature materials (Inconel 718, Hastelloy X) with high-pressure coolant (70 bar) to prevent chip welding and maintain surface finish in aerospace engine applications.

Bar feeder systems (6–50mm diameter capacity) enable continuous production of long-shaft parts (length-to-diameter ratio 30:1) with zero setup time between batches, supported by automatic tool changers (20+ stations) .

AI-driven scheduling (using Siemens MindSphere) reduces machine downtime by 25%, ensuring consistent lead times (3–15 days) with real-time production monitoring and predictive maintenance alerts.

Offer type II/III anodizing (12–25 μm thickness for aluminum), electroplating (gold, nickel, chrome for conductivity/wear), and PTFE coating (low friction coefficient ≤0.05) for bearing surfaces.

Medical parts undergo USP Class VI biocompatibility testing and electropolishing (Ra ≤0.08 μm) for implantable devices and surgical tools .

Automotive: Transmission input shafts (balance tolerance ≤0.01g·mm), fuel injector nozzles (micro-orifice accuracy ±0.003mm), and CV joint components with splined features.

Medical: Surgical drill bits (Ra 0.4 μm finish for tissue compatibility), orthopedic pins with self-tapping threads, and catheter guide wires with laser-marked depth indicators.

Aerospace: Turbine compressor blades (±0.005 mm profile accuracy for aerodynamic efficiency), landing gear actuator rods ( fatigue-tested to 10⁷ cycles), and hydraulic valve spools.

Industrial: Hydraulic cylinder rods (straightness ≤0.002 mm/m), bearing races with tight runout control, and precision lead screws with ball nut compatibility.

Design for Manufacturability (DFM) Support: Free analysis of threaded features (ISO metric, UN imperial, ACME), chamfer angles, and undercut dimensions to optimize part geometry for turning, reducing cycle time by 10–15%.

Complex Geometry Solutions: Expertise in micro-turning (features ≤0.5mm for microelectronics) and deep hole drilling (aspect ratio 20:1 using gun drills) for fuel injectors and optical components.

Full Traceability: QR-code labeling linked to CMM inspection reports, material certificates (EN 10204 3.1), and process parameters (spindle speed, feed rate) for automotive and aerospace audit compliance.