Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

![]()

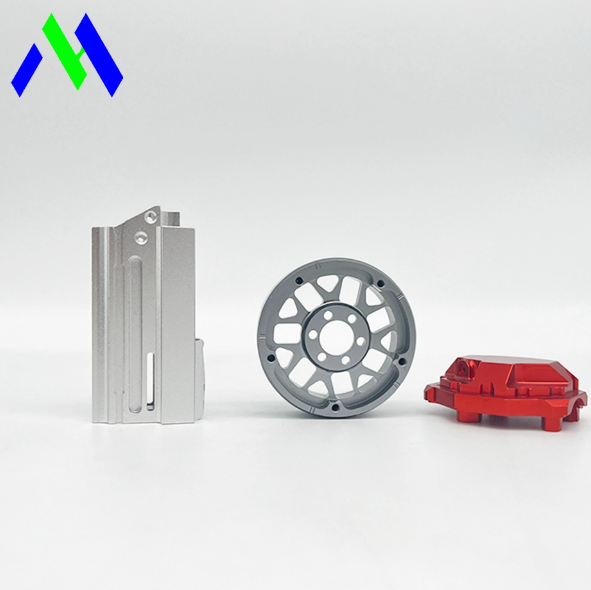

| Name | Custom Precision Parts CNC 5 Axis Machining Center Micro Machining Mechanical Parts |

| Place of Origin | Guangdong, China |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Model Number | OEM |

| Keyword | CNC machining Aluminum Service custom metal parts |

| Material | Plastic:Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| Surface Treatment | Stainless Steel/Titanium/Aluminum/Brass etc |

| Process | CNC turning and milling |

| Surface treatment | Customer's Request |

| Service | Customized OEM CNC Machining |

Our micro-machining division specializes in miniature components requiring sub-micron accuracy for advanced medical, optical, and microfluidic applications. Equipped with 5-axis ultra-precision machining centers featuring 0.1μm resolution linear scales and 20,000 RPM air-bearing spindles, we machine features as small as 0.02mm in diameter. Specialized processes include micro-milling of biocompatible cobalt-chrome (ASTM F75), micro-turning of optical-grade brass (C36000), and diamond machining of IR-transparent zinc selenide. For high-volume micro parts, our Swiss-type CNC lathes with guide bushings achieve ±1μm diameter tolerances on 0.3mm brass pins. All processes are conducted in Class 7 cleanrooms when required, with electrostatic discharge (ESD) protection for sensitive electronics components.

· Sub-Surface Damage Control: Ductile-mode machining of brittle materials.

· Micro-EDM Capability: 0.03mm wire EDM for tungsten micro-electrodes.

· In-Process Probing: Renishaw touch probes verify dimensions without unclamping.

· Biocompatibility Certification: Full material traceability per FDA 21 CFR 820.

· Nanofinishing: Magnetorheological polishing for Ra 0.02μm optical surfaces.

· Microelectronics: MEMS sensor housings, wafer probe cards.

· Photonics: Fiber optic ferrules, laser collimator mounts.

· Medical: Orthodontic bracket slots, micro-needle arrays.

· Watchmaking: Escapement wheels, balance staffs.

1. How are micro-tools maintained during long runs?

Laser tool presetters and acoustic emission monitoring enable automatic tool change.

2. Can you machine MRI-compatible materials?

Yes, titanium alloys and ceramic composites with magnetic permeability <1.01.

3. What’s your approach to micro-deburring?

Combination of CO2 snow blasting and micro-abrasive flow machining.

4. Do you provide micro-assembly services?

Vacuum tweezer systems assemble parts under 10x magnification inspection.